We use cookies to make your experience better. Read more

Master Valves

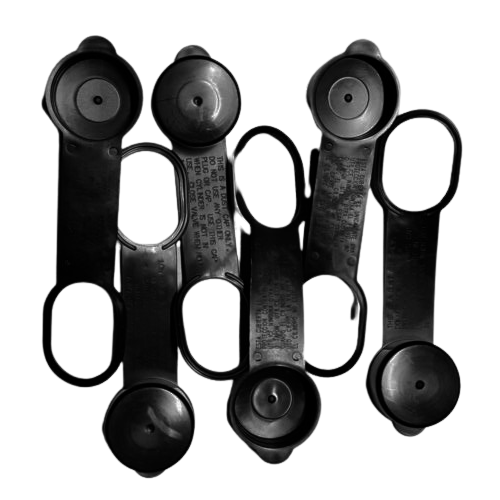

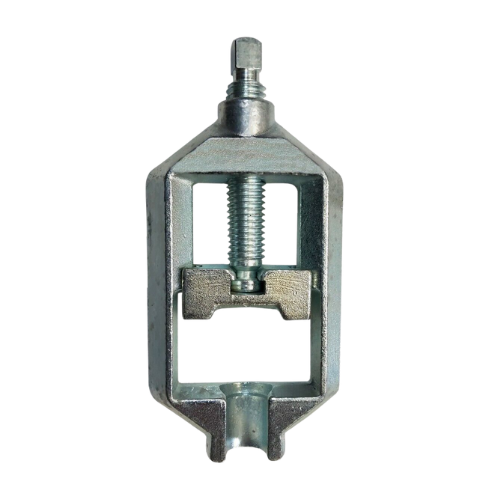

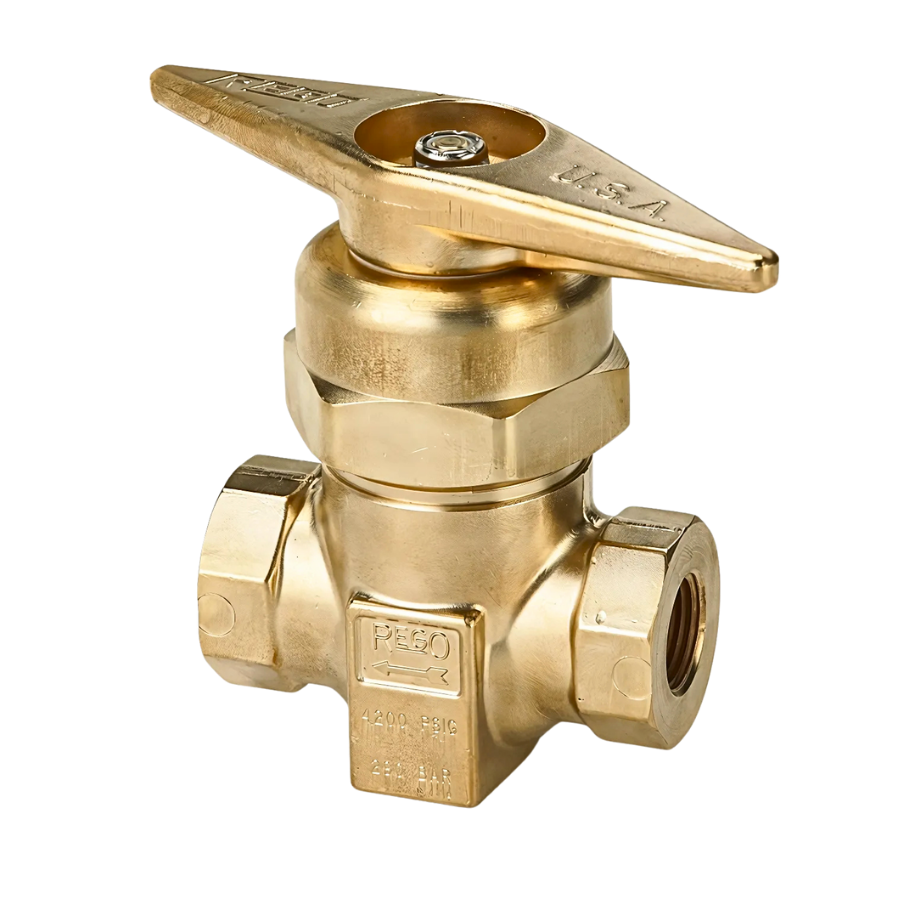

Diaphragm Master Valves are compactly designed for heavy duty use in liquefied gas applications, butane, fuel gas, propane, flammables and refrigerants. These valves are safe to use on tube trailers, manifold systems and other piping systems too.JTC Valves lists master valves manufactured by Sherwood and Rego, both trusted for adhering to stringent quality control processes, at very economical prices.The HP9560 series master valves exhibit a low operating torque, which makes it very easy for manual operation. This valve is widely used in high pressure applications on tube trailers, cylinder filling panels and other high pressure systems.

- Body, bonnet, stem, seat retainer, stern seal, retaining rings and washer of brass. Handwheel washer made of PCTFE. Large brass handwheel for ease of use under high pressure. Maximum working pressure is 5600 PSI (386 bars). Non rise stem design. Viton O-ring seal for durability. Soft seal valve uses CTFE seat disc for bubble tight seal (useful for hydrogen, helium service). Copper seat disc in seat retainer creates a seal against Monel body. Metal seat reduces the possibility of seat decomposition. Temperature range: -40°F to +165°F. As per CGA G-4.1, all valves are cleaned for oxygen use. 100% factory tested for complete safety.

Browse Catalog

Shop By

Shopping Options

Price

Manufacturer

Shipping & Delivery

hidden

Free shipping

Free shipping on all US order or order above $200

hidden

Support 24/7

Contact us 24 hours a day

hidden

30 Day return

Simply return it within 30 days for an exchange.

hidden

100% PaymentT secure

We ensure secure payment with PEV